In this experiment, the membrane treatment method was combined with the alcohol production termination method. Hollow fiber ultrafiltration membrane was used to remove excess yeast cells and reduce the alcohol production of yeast at the late fermentation stage to prepare low alcohol wine. It can maximize the preservation of the original taste and various functional ingredients in the wine, and it is cheap to produce and easy to operate.

Test method for

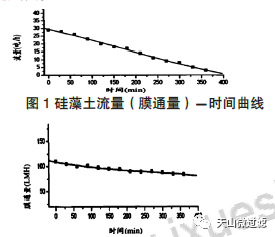

The hours and flow of tartar removal by dead-end filtration (taking diatomite filtration as an example) and the hours and membrane flux of tartar removal by membrane separation were recorded, and the flow-time curve (membrane flux) was made to compare the filtration performance of the two, as shown in Figure 2. The main physical and chemical indicators of wine shall be tested according to the wine industry manual. The sensory evaluation test of wine quality changes, using triangulation tasting method.

Membrane assembly selection

With the increase of ultrafiltration time, the flux decreases gradually, but the rate of change is not the same. In the first few minutes, the membrane flux decreases rapidly. This is because at the beginning of ultrafiltration, the gel layer keeps thickening and the concentration polarization keeps increasing, which makes the resistance increase rapidly and leads to the membrane flux decreases greatly. After 20min of ultrafiltration, the decrease of membrane flux decreases and gradually tends to be stable, because a stable boundary layer has been established on the membrane surface

Tends to be saturated so that the membrane flux is relatively stable; When the ultrafiltration time approached 2h, the membrane flux showed a trend of slow decline again. This was because with the progress of ultrafiltration, the concentration multiple of samples increased and macromolecular materials continued to deposit, resulting in intensified membrane surface pollution and further decreased membrane flux. The two kinds of ultrafiltration membranes with different molecular weight interception have the same change rule during ultrafiltration. Therefore, during the test, the membrane permeability was stabilized by ultrafiltration for 20min, and then the ultrafiltration was repeated for 60min to 100min.

Cleaning and regeneration ability of filter membrane

The regeneration ability of membrane is an important performance of membrane materials, which reflects the reusable ability and economic performance of membrane materials, and directly affects the promotion and application of membrane. It was found that the flux of CMF membrane was basically restored to the original level after being polluted by a simple hot water cleaning, while the filtration performance was improved as a whole, especially significantly during the filtration process, due to the deep cleaning of the membrane after hot alkali cleaning. The experimental results show that CMF membrane material has good cleaning and regeneration ability, but also indicates that the membrane pollution is mainly concentrated on the membrane surface, not embedded in the membrane hole, the deposition of pollutants may be relatively loose and easy to remove.

In microporous filtration, the initial filtration pressure is a very important process parameter. If the pressure is too large, the radial force will weaken the effect of shear force, reduce the mass transfer coefficient (K), accelerate the concentration polarization of the membrane surface, promote the blockage and embedding of pollutants into the membrane hole, and easily cause the deep pollution of the membrane. The CMF equipment used in this experiment can adjust the working pressure indirectly through the flow rate. It was found in the experiment that when the flow rate was not controlled at the initial stage of filtration, the flow rate attenuated rapidly, and the time kept above 33.3L/(h·m2) was only 4h, and then decreased to 15.0L/h after 8h. After flow control, the time kept above 33.3L/(h·m2) could reach 6h. The flow rate remained at 28.3L/(h·m2) after 9h.

Effects of CMF filtration on main physical and chemical indexes of red wine.

The main physical and chemical indexes of wine were tested. After CMF filtration, the stability and bacterial indexes of wine reached the standard, the main physical and chemical indexes of wine degree, total acid, volatile acid, pH value, chroma and tannin changed little, and the indexes of reducing sugar, total SO2 and free SO2 decreased slightly. FIG. 1 shows the changes of pentosan in liquor before and after ultrafiltration treatment.

Post time: Jul-19-2022